Máy công cụ CNC (Điều khiển số máy tính) đóng vai trò then chốt trong sản xuất hiện đại, đóng vai trò là xương sống của gia công chính xác và sản xuất công nghiệp. Những công cụ này được thiết kế để thực hiện các nhiệm vụ cắt, tạo hình, khoan và hoàn thiện phức tạp với độ chính xác và hiệu quả vô song.

Sự tích hợp của họ vào quy trình sản xuất đã làm thay đổi các ngành công nghiệp như hàng không vũ trụ, ô tô, chăm sóc sức khỏe và điện tử, nơi độ chính xác và tính nhất quán cao là điều tối quan trọng.

Tầm quan trọng của Máy công cụ CNC nằm ở khả năng nâng cao hiệu quả, độ chính xác và năng suất. Không giống như các công cụ thủ công, máy công cụ CNC hoạt động với các hướng dẫn được lập trình sẵn, đảm bảo rằng mọi thao tác cắt hoặc chuyển động đều được thực hiện với độ chính xác chính xác. Điều này giúp giảm lãng phí vật liệu, giảm thiểu lỗi của con người và đẩy nhanh tiến độ sản xuất.

Ví dụ, một dao phay được chọn phù hợp có thể tăng sản lượng trong khi vẫn duy trì dung sai chặt chẽ, điều này rất quan trọng đối với các bộ phận yêu cầu độ chính xác kích thước cao.

Tuy nhiên, việc chọn sai công cụ CNC có thể dẫn đến những thách thức đáng kể. Lựa chọn công cụ kém có thể dẫn đến vết cắt không đều, dụng cụ bị mòn sớm hoặc thậm chí làm hỏng phôi hoặc bản thân máy.

Ví dụ: sử dụng một công cụ không phù hợp với vật liệu được gia công có thể gây ra hiện tượng quá nhiệt hoặc sứt mẻ, dẫn đến tăng thời gian ngừng hoạt động và chi phí vận hành cao hơn. Do đó, hiểu cách chọn máy công cụ CNC phù hợp là điều quan trọng đối với các doanh nghiệp muốn tối ưu hóa quy trình sản xuất của mình.

Bài viết này sẽ cung cấp hướng dẫn toàn diện về máy công cụ CNC, bắt đầu với định nghĩa và loại của chúng, sau đó đi sâu vào các yếu tố chính cần xem xét khi chọn chúng. Bằng cách hiểu những nguyên tắc cơ bản này, nhà sản xuất có thể đưa ra quyết định sáng suốt để đảm bảo hiệu suất và độ bền của công cụ tối ưu.

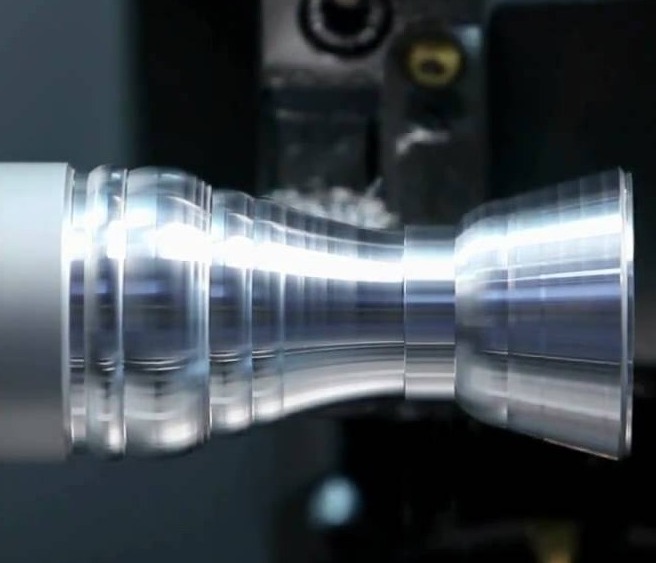

Máy công cụ CNC là thiết bị chuyên dụng được sử dụng trong các quy trình gia công tự động để tạo hình, cắt hoặc hoàn thiện vật liệu thành các dạng chính xác. Chúng được vận hành bởi hệ thống CNC, thực hiện các hướng dẫn được lập trình sẵn để thực hiện các nguyên công gia công cụ thể. Những công cụ này rất cần thiết cho các nhiệm vụ đòi hỏi độ chính xác và độ lặp lại cao, khiến chúng không thể thiếu trong môi trường sản xuất.

Điều quan trọng là phải phân biệt máy công cụ CNC với máy CNC. Trong khi một máy CNC đề cập đến toàn bộ thiết lập—bao gồm thân máy, hệ thống điều khiển và các bộ phận chuyển động—thuật ngữ “máy công cụ CNC” đặc biệt đề cập đến các bộ phận được sử dụng để cắt, khoan hoặc tạo hình vật liệu.

Ví dụ bao gồm dao phay, dụng cụ tiện và đá mài. Dụng cụ là phần giao tiếp giữa máy CNC và phôi, ảnh hưởng trực tiếp đến chất lượng của thành phẩm.

Máy công cụ CNC có thể được phân loại thành ba loại dựa trên ứng dụng của chúng:

1. Dụng cụ cắt:

○ Máy phay: Được sử dụng để loại bỏ vật liệu để tạo ra các hình dạng và bề mặt chính xác.

○ Máy khoan: Lý tưởng để tạo các lỗ có kích thước và độ sâu khác nhau.

○ Dụng cụ tiện: Được sử dụng trong máy tiện để tạo hình các bộ phận hình trụ bằng cách loại bỏ vật liệu.

2. Công cụ hoàn thiện:

○ bánh mài: Đảm bảo lớp hoàn thiện mịn và kích thước chính xác bằng cách loại bỏ lượng vật liệu rất nhỏ.

○ Dụng cụ đánh bóng: Tăng cường chất lượng bề mặt và độ bóng, thường được sử dụng cho mục đích trang trí hoặc chức năng.

3. Dụng cụ chuyên dụng:

○ Dụng cụ khắc: Tạo các mẫu hoặc dấu hiệu phức tạp trên bề mặt.

○ Công cụ khai thác: Dùng để cắt ren trong trong các lỗ.

○ Dụng cụ vát mép: Được sử dụng để tạo các cạnh vát nhằm mục đích chức năng hoặc thẩm mỹ.

Hiệu suất của máy công cụ CNC phụ thuộc vào vật liệu và lớp phủ của chúng. Vật liệu công cụ phổ biến bao gồm:

● cacbua: Được biết đến với độ cứng và khả năng chịu nhiệt, khiến nó trở nên lý tưởng cho các ứng dụng tốc độ cao.

● Thép tốc độ cao (HSS): Cung cấp độ dẻo dai và khả năng chống mài mòn tốt cho gia công đa năng.

● Gốm sứ: Thích hợp cho các hoạt động ở nhiệt độ cao và vật liệu cứng như gang.

Ngoài thành phần vật liệu, lớp phủ dụng cụ đóng một vai trò quan trọng trong việc cải thiện hiệu suất và tuổi thọ của dụng cụ. Các lớp phủ như titan nitride (TiN) và nhôm oxit (Al₂O₃) làm giảm ma sát, tăng cường khả năng chống mài mòn và cải thiện hiệu quả cắt. Ví dụ: dụng cụ cacbua có lớp phủ TiN có thể xử lý tốc độ cao hơn và tồn tại lâu hơn đáng kể so với dụng cụ không được phủ.

Việc lựa chọn máy công cụ CNC phù hợp đòi hỏi phải đánh giá cẩn thận các yếu tố khác nhau để đảm bảo hiệu quả, độ bền và độ chính xác trong hoạt động gia công. Dưới đây là bảng phân tích các cân nhắc chính:

Loại vật liệu được gia công đóng một vai trò quan trọng trong việc lựa chọn công cụ. Các kim loại cứng như thép hoặc titan đòi hỏi các công cụ bền chắc như cacbua hoặc gốm, có thể chịu được nhiệt độ cao và chống mài mòn.

Ngược lại, các vật liệu mềm hơn như nhựa, vật liệu tổng hợp hoặc gỗ phù hợp hơn với các dụng cụ bằng thép tốc độ cao (HSS), mang lại độ linh hoạt và độ sắc nét cao hơn. Ví dụ, dao phay có cạnh sắc và lớp phủ ma sát thấp hoạt động tốt với nhôm, trong khi các dụng cụ được phủ kim cương là lý tưởng để gia công vật liệu tổng hợp.

Quy mô sản xuất xác định độ bền và loại công cụ cần thiết. Đối với sản xuất số lượng lớn, các công cụ có lớp phủ tiên tiến và khả năng chống mài mòn lâu dài, như các công cụ cacbua phủ titan nitride, là rất cần thiết để sử dụng lâu dài. Ngược lại, sản xuất hàng loạt nhỏ hoặc tạo nguyên mẫu có thể ưu tiên các công cụ tiết kiệm chi phí hơn là tuổi thọ.

Dung sai chặt chẽ và thiết kế phức tạp đòi hỏi các công cụ chuyên dụng có độ chính xác cao. Các ngành công nghiệp như sản xuất thiết bị y tế và hàng không vũ trụ đòi hỏi các công cụ cực kỳ chính xác như máy phay vi đầu hoặc công cụ phủ kim cương, đảm bảo độ hoàn thiện hoàn hảo và độ chính xác về kích thước.

Hình dạng và kích thước của dụng cụ ảnh hưởng trực tiếp đến hiệu suất cắt. Ví dụ: các công cụ có góc nhọn là tối ưu cho việc tạo rãnh, trong khi các công cụ được làm tròn phù hợp hơn cho việc tạo đường viền. Các ứng dụng tạo ren có thể yêu cầu các taro ren hoặc máy phay ren có hình dạng độc đáo để vận hành hiệu quả.

Các lớp phủ dụng cụ như titan nitride hoặc nhôm oxit nâng cao hiệu suất bằng cách giảm ma sát, cải thiện khả năng chịu nhiệt và kéo dài tuổi thọ dụng cụ. Những lớp phủ này đặc biệt có lợi cho các ứng dụng tốc độ cao hoặc gia công vật liệu mài mòn.

Khả năng tương thích của một công cụ với tốc độ cắt, tốc độ tiến dao và độ sâu cắt cụ thể là điều cần thiết để đạt được kết quả tối ưu. Các công cụ có thể hoạt động ở thông số cao hơn sẽ cải thiện năng suất mà không ảnh hưởng đến chất lượng.

Độ ổn định của dụng cụ phụ thuộc vào đầu cặp và trục xoay tương thích. Việc lựa chọn các công cụ phù hợp với thông số kỹ thuật về tốc độ, mô-men xoắn và công suất của máy sẽ đảm bảo vận hành liền mạch và giảm nguy cơ hỏng dụng cụ.

Cân bằng chi phí với chất lượng là rất quan trọng. Đầu tư vào các công cụ chất lượng cao thường giúp tiết kiệm lâu dài nhờ giảm hao mòn, ít thay thế hơn và cải thiện hiệu quả gia công, đảm bảo lợi tức đầu tư (ROI) tốt hơn.

Bằng cách xem xét cẩn thận các yếu tố này, nhà sản xuất có thể chọn máy công cụ CNC phù hợp với nhu cầu sản xuất và mục tiêu vận hành của họ.

Việc lựa chọn một nhà cung cấp đáng tin cậy cũng quan trọng như việc chọn đúng máy công cụ CNC. Danh tiếng của nhà cung cấp, dịch vụ hỗ trợ và việc tuân thủ các tiêu chuẩn chất lượng có thể tác động đáng kể đến hiệu quả và tuổi thọ của các công cụ của bạn.

Các công cụ tìm nguồn cung ứng từ các thương hiệu hoặc nhà cung cấp đáng tin cậy đảm bảo tính nhất quán về chất lượng và hiệu suất. Các nhà cung cấp có uy tín thường có thành tích đã được chứng minh trong việc cung cấp các công cụ bền bỉ phù hợp với nhiều ứng dụng khác nhau. Khi đánh giá một nhà cung cấp, hãy tìm kiếm các đánh giá của khách hàng, nghiên cứu điển hình hoặc lời chứng thực nêu bật độ tin cậy của họ. Ví dụ.

Các nhà cung cấp cung cấp hỗ trợ kỹ thuật chuyên môn là vô giá, đặc biệt đối với các doanh nghiệp cần trợ giúp để lựa chọn công cụ phù hợp cho các ứng dụng cụ thể. Các nhà cung cấp đáng tin cậy cung cấp hỗ trợ sau bán hàng, chẳng hạn như bảo hành, thay thế công cụ và dịch vụ bảo trì, đảm bảo hoạt động không bị gián đoạn. Hướng dẫn này có thể tiết kiệm thời gian và giảm rủi ro khi mua các công cụ không tương thích hoặc kém chất lượng.

Trong các ngành đòi hỏi các hoạt động gia công chuyên dụng, các công cụ CNC tùy chỉnh là rất cần thiết. Cung cấp các giải pháp công cụ riêng biệt cho các ứng dụng độc đáo, giúp các ngành như hàng không vũ trụ, ô tô và y tế đáp ứng các yêu cầu cụ thể của họ.

Các chứng chỉ như ISO hoặc CE đảm bảo rằng máy công cụ CNC đáp ứng các tiêu chuẩn an toàn và chất lượng nghiêm ngặt. Các công cụ từ các nhà cung cấp được chứng nhận đảm bảo hiệu suất vượt trội và tuân thủ các quy định sản xuất toàn cầu, mang đến sự an tâm cho khách hàng.

Hợp tác với nhà cung cấp có uy tín đảm bảo khả năng tiếp cận các công cụ chất lượng cao, hướng dẫn của chuyên gia và tính linh hoạt để đáp ứng nhu cầu sản xuất của bạn.

Việc chọn đúng máy công cụ CNC đòi hỏi phải đánh giá cẩn thận để đảm bảo chúng đáp ứng nhu cầu của quy trình sản xuất của bạn. Đánh giá chất lượng trước khi mua có thể tiết kiệm thời gian, tiền bạc và công sức về lâu dài.

Dụng cụ chất lượng cao được đặc trưng bởi các vật liệu chắc chắn như cacbua, thép tốc độ cao (HSS) hoặc gốm sứ. Kiểm tra chất lượng xây dựng bằng cách tìm kiếm tính đồng nhất và độ chính xác trong xây dựng. Tránh các dụng cụ có khuyết tật nhìn thấy được, bề mặt không bằng phẳng hoặc lớp hoàn thiện không đạt tiêu chuẩn vì những dụng cụ này có thể dẫn đến hiệu suất kém hoặc bị mài mòn sớm.

Đánh giá của khách hàng và nghiên cứu điển hình cung cấp những hiểu biết sâu sắc có giá trị về hiệu suất của công cụ. Phản hồi từ người dùng trong các ngành tương tự giúp đánh giá độ bền, hiệu quả cắt và độ tin cậy. Nhiều nhà cung cấp chia sẻ các nghiên cứu điển hình cho thấy công cụ của họ vượt trội như thế nào trong các ứng dụng cụ thể, khiến chúng trở thành nguồn tài nguyên hữu ích cho việc ra quyết định sáng suốt.

Trước khi cam kết mua hàng, hãy tiến hành chạy thử để đánh giá hiệu suất của công cụ. Kiểm tra dụng cụ trên các vật liệu dự định để theo dõi hiệu quả cắt, chất lượng hoàn thiện bề mặt và độ mòn của dụng cụ. Đánh giá thực tế này đảm bảo công cụ sẽ đáp ứng yêu cầu của bạn và mang lại kết quả tối ưu trong điều kiện thực tế.

Việc chọn sai máy công cụ CNC có thể làm gián đoạn quá trình sản xuất, tăng chi phí và ảnh hưởng đến chất lượng sản phẩm. Tránh những lỗi phổ biến này để đảm bảo quá trình sản xuất diễn ra suôn sẻ:

Mỗi vật liệu — dù là kim loại, nhựa hay composite — đều yêu cầu các công cụ phù hợp với đặc tính của nó. Việc sử dụng các dụng cụ không phù hợp với vật liệu có thể dẫn đến hiệu suất cắt kém, làm hỏng dụng cụ hoặc độ hoàn thiện sản phẩm kém chất lượng. Luôn ưu tiên các công cụ được thiết kế dành riêng cho vật liệu bạn làm việc.

Các công cụ không tương thích với kích thước, tốc độ hoặc mô-men xoắn trục chính của máy CNC có thể dẫn đến hoạt động không ổn định và giảm hiệu quả. Các công cụ không khớp cũng có thể gây hư hỏng cho máy hoặc ảnh hưởng đến độ chính xác. Luôn xác minh tính tương thích với thông số kỹ thuật của máy trước khi mua.

Mặc dù hạn chế về ngân sách là quan trọng nhưng việc ưu tiên chi phí hơn chất lượng có thể dẫn đến chi phí dài hạn cao hơn do phải thay thế thường xuyên hoặc hiệu suất kém. Đầu tư vào các công cụ bền bỉ, chất lượng cao sẽ mang lại ROI tốt hơn và giảm thời gian ngừng hoạt động do lỗi công cụ.

Việc không xem xét nhu cầu bảo trì có thể rút ngắn tuổi thọ của công cụ và giảm năng suất. Hãy lựa chọn những công cụ dễ bảo trì và đảm bảo bảo trì thường xuyên để tối đa hóa hiệu quả và tuổi thọ của chúng.

Bằng cách tránh những cạm bẫy này và tiến hành đánh giá kỹ lưỡng, doanh nghiệp có thể chọn các công cụ máy CNC giúp nâng cao hiệu quả, độ chính xác và năng suất tổng thể.

Bảo trì đúng cách là điều cần thiết để đảm bảo máy công cụ CNC hoạt động tối ưu và bền lâu hơn. Bằng cách áp dụng các phương pháp hiệu quả, doanh nghiệp có thể giảm thời gian ngừng hoạt động, nâng cao hiệu quả và giảm thiểu chi phí.

Bảo trì thường xuyên là rất quan trọng để giữ cho các công cụ ở tình trạng tốt nhất. Vệ sinh dụng cụ sau khi sử dụng sẽ loại bỏ các mảnh vụn và giảm nguy cơ rỉ sét hoặc mài mòn. Việc mài sắc các cạnh cắt duy trì độ chính xác và hiệu quả, đồng thời thay thế các dụng cụ bị mòn sẽ ngăn ngừa hư hỏng máy và phôi. Tuân theo lịch trình bảo trì được khuyến nghị, chẳng hạn như vệ sinh hàng ngày và kiểm tra định kỳ, đảm bảo hiệu suất ổn định và ngăn ngừa những hỏng hóc đột ngột.

Bảo quản và xử lý đúng cách có thể kéo dài đáng kể tuổi thọ của các công cụ CNC. Dụng cụ phải được bảo quản trong các ngăn hoặc hộp bảo vệ được chỉ định để tránh hư hỏng vật lý và tránh tiếp xúc với độ ẩm hoặc chất gây ô nhiễm. Khi xử lý dụng cụ, hãy sử dụng các biện pháp an toàn thích hợp như đeo găng tay và tránh làm rơi hoặc xử lý sai cách. Những bước đơn giản này đảm bảo các công cụ vẫn còn nguyên vẹn và sẵn sàng để sử dụng.

Giám sát độ mòn của dụng cụ là chìa khóa để duy trì hiệu quả và ngăn ngừa sự cố không mong muốn. Các dấu hiệu mòn, chẳng hạn như các cạnh bị xỉn màu hoặc vết cắt không đều, cho thấy dụng cụ cần được thay thế. Hệ thống giám sát nâng cao có thể theo dõi hiệu suất của công cụ trong thời gian thực, cảnh báo cho người vận hành khi công cụ đạt đến giới hạn hao mòn. Cách tiếp cận chủ động này giúp tăng cường độ chính xác và giảm lãng phí.

Nói chung, việc lựa chọn máy công cụ CNC phù hợp là rất quan trọng để tối ưu hóa quy trình sản xuất và đảm bảo chất lượng sản phẩm. Bằng cách xem xét các yếu tố như loại vật liệu, khối lượng sản xuất, yêu cầu về độ chính xác và hình dạng công cụ, nhà sản xuất có thể đưa ra những lựa chọn sáng suốt nhằm nâng cao hiệu quả và giảm chi phí vận hành.

Ngoài ra, việc chọn nhà cung cấp đáng tin cậy và đánh giá chất lượng dụng cụ trước khi mua là những bước cần thiết để tránh những sai lầm tốn kém và đảm bảo hiệu suất lâu dài của dụng cụ. Thực hành bảo trì và bảo quản đúng cách giúp kéo dài tuổi thọ của các công cụ CNC, góp phần duy trì năng suất.

Cuối cùng, việc hiểu được những cân nhắc quan trọng này sẽ giúp doanh nghiệp lựa chọn máy công cụ CNC tốt nhất, giúp cải thiện hiệu quả hoạt động, sản phẩm chất lượng cao hơn và lợi nhuận cao hơn.