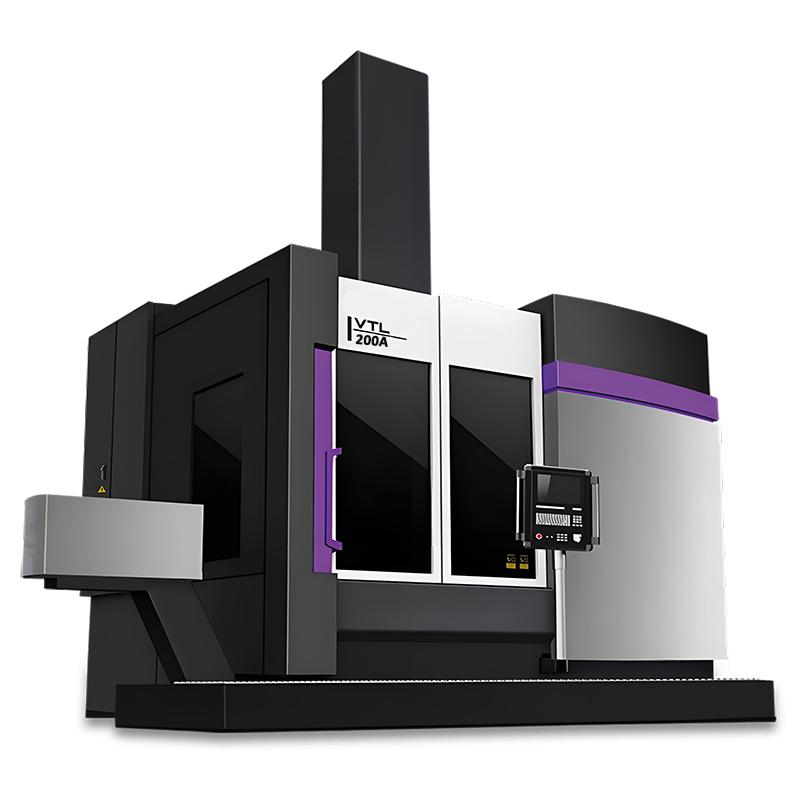

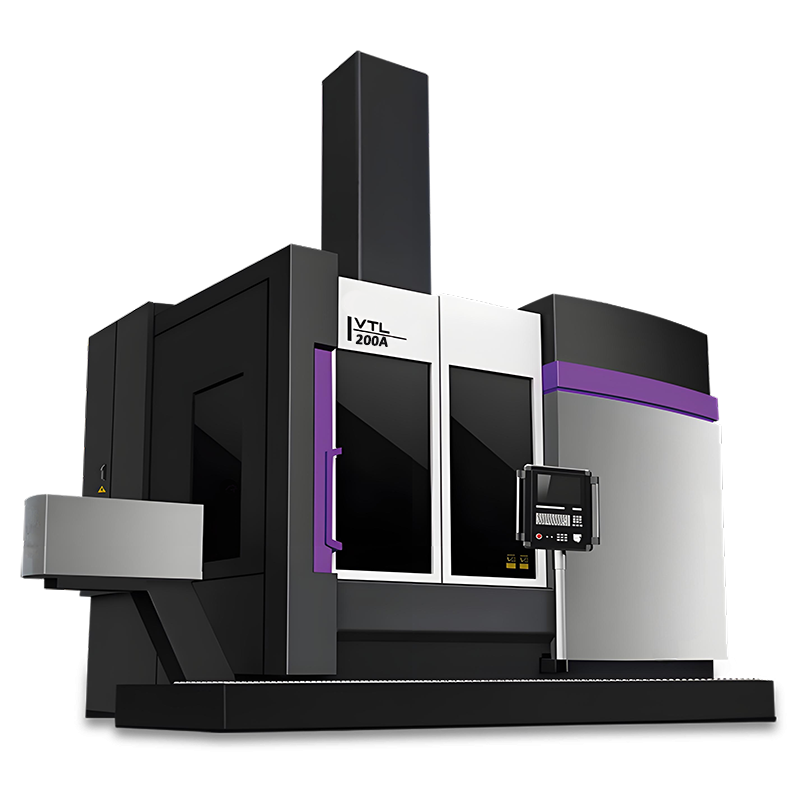

CNC Lathe Machine is a type of computer-controlled machine tool.CNC lathes offer extremely accurate machining. This lathe is suitable for large parts machining in industries of power stations, shipbuilding, metallurgy, mining, etc.

tối đa. Du lịch trục X :

-100~+1650mmmtối đa. Hành trình trục Z :

1200mmChiều cao phôi tối đa :

1800mmTrọng lượng phôi tối đa :

10000kgĐăng kí :

Power generation, shipbuilding, metallurgy, and mining.Main Structure of CNC Vertical Lathe Machine

|

The lathe machine adopts a structure with full protection of the main machine, and a centralized layout of mechanical, electrical, and hydraulic systems. It is mainly composed of a machine, a tool holder, X, Z direction movement, and worktable axis rotation, milling axis B, an operating console, an automatic chip conveyor, automatic lubrication, a hydraulic system, a tool magazine, protection, an electronic control system, and an electronic control box. The machine tool can be equipped with an in-machine tool setting device, which can realize an automatic tool changing device, automatic processing, improve processing quality, and reduce operating costs. |

Workbench Introduce

The workbench is made of HT300 grade gray iron cast as a whole, annealed, and stress-eliminated before fine machining. It adopts a structure design with radial ribs and annular ribs, with a diameter of 1800mm and sufficient thickness and rigidity. The standard configuration is a manual four-jaw chuck, and the workbench surface is designed with 20 radial 22mm T-slots for positioning and clamping workpieces.

The main drive of the workbench uses a main motor, a set of gear reduction box, and a large gear ring to drive the workbench to rotate. During turning, the main motor drives a two-speed gear reducer through a belt to drive the pinion to drive the gear ring to realize the rotation of the workbench. The workbench guide adopts a rolling guide structure, which has the characteristics of large load-bearing capacity, small friction coefficient, high stability, and easy maintenance. The workbench spindle bearing, rolling guide and main gearbox lubrication adopts an independent hydraulic system to supply oil, and is equipped with an oil temperature cooler to control the lubricating oil temperature within the set range, thereby ensuring the working accuracy of the workbench.

Key Technology Parameters

| Item | unit | Specification | |

| Main Parameters | Workbench diameter | mm | 1800 |

| Maximum rotation diameter | mm | 2100 | |

| Maximum turning diameter | mm | 2000 | |

| Maximum workpiece height | mm | 1800 | |

| Maximum workpiece weight | Kg | 10000 | |

| Maximum torque of worktable | N.m | 22500 | |

| Main tooth Wheel Box | Spindle speed range | r/min | 1.5-200 |

| Workbench speed change gear | block | Two-speed infinite | |

| Main Motor Output Power | 30 minute rating | kW | 45 |

| Continuous Rating | kW | 37 | |

| Slip Pillow | Ram body cross-sectional dimensions | mm×mm | ☑220X220 |

| X -axis travel | mm | -100~+1650 | |

| Z-axis travel | mm | 1200 | |

| Beam | Crossbeam travel | mm | 1200 (6X200) |

| Feed speed | Cutting feed speed | mm/rev | 0.2 ~ 1000 mm/min |

| Rapid feed rate | mm/min | 6000 | |

| Tool holder | Single tool holder | 1 | |

| Turning tool bar size | mm×mm | 32×32 | |

| Tool Magazine | Broach type T type | Number of tools | 8 |

| Weight | Total weight of machine tool | Kg | Approximately 39,500 |

| System | CNC device model | FANUC oi TF | |

| Machine Appearance | Length × Width × Height | mm×mm×mm | 6700x4250x |

| 6500 | |||

| Total Electricity Source | Voltage | V | AC380 |

| Voltage fluctuation range | -10 to 10% | ||

| frequency | Hz | 50 ±1 | |

| Total power | kW | 60 | |

| Total Power Source | Main motor | kW | 37/45 |

| Hydraulic motor | kW | 2.2 | |

| Cooling pump motor | kW | 0.75 | |

| X -axis servo motor | Nm | 22 | |

| Z -axis servo motor | Nm | 22 | |

| Lifting motor | kW | 6.5 | |

| NC unit | KVA | 0.05 | |

| Control Panel | KVA | 0.02 | |

| Fan motor fluorescent lamp etc. | kW | 0.16 | |

| Chip conveyor motor | kW | 0.75 | |

| Hydraulic system pressure | Mpa | 5 | |

thẻ :