Sản xuất và gia công các bộ phận yêu cầu chúng được sản xuất chính xác và nhiều lần, vì vậy máy CNC (điều khiển số máy tính) là rất đáng kể. Các loại máy CNC được sử dụng rộng rãi nhất là các trung tâm gia công và giàn thẳng đứng. Về mặt các loại ứng dụng, cả hai đều có điểm mạnh và điểm yếu. Bài viết này xem xét các điểm cần thiết của sự khác biệt giữa hai máy này để xác định cái nào phù hợp nhất cho các yêu cầu máy khác nhau.

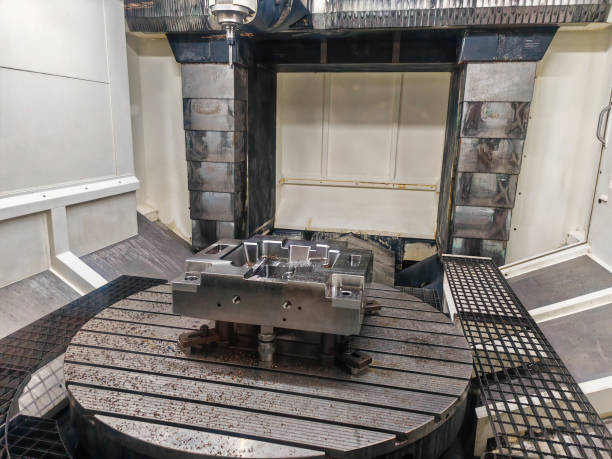

Máy CNC Gantry bao gồm một chùm ngang mà không gian làm việc được kéo dài và gắn trên hai hỗ trợ bên. Chùm tia này bao gồm một phụ tùng trục chính hoặc công cụ cắt, có thể được di chuyển theo ba trục tuyến tính (X, Y, Z). Điều này cung cấp định vị chính xác trên một khu vực làm việc tuyệt vời để hoàn thiện các bộ phận lớn.

Máy CNC Gantry Có một khung giống như cây cầu gọi là một giàn. Gantry này có đường ray cho phép một đầu trục chính di chuyển từ trái sang phải và về phía trước. Đầu trục chính giữ công cụ cắt và di chuyển dọc theo trục X và Y. Công cụ cắt được hạ xuống xuống trên trục Z để chạm vào phôi. Chuyển động của đầu trục chính được điều khiển chính xác bởi một máy tính theo một đường dẫn được lập trình. Điều này cho phép máy CNC Gantry cắt, khoan và nghiền chính xác các bộ phận kim loại hoặc gỗ lớn bằng cách định vị chính xác công cụ cắt quay theo hướng dẫn mã CNC được tải vào máy tính. Xây dựng giàn cung cấp sự ổn định để xử lý các bộ phận lớn.

Một tính năng nổi bật là phong bì công việc lớn. Cấu trúc khung Gantry cho phép di chuyển tuyến tính của nhiều mét trong cả trục X và Y. Khu vực làm việc quá khổ này phù hợp để gia công các bộ phận cực kỳ lớn vượt quá khả năng của các máy CNC điển hình. Trên các máy giàn dài dài, các bộ phận có chiều dài trên 5 mét có thể được xử lý.cnc

Một tính năng đáng chú ý khác là phần truy cập phần không bị cản trở được cung cấp bởi hướng ngang. Có quyền truy cập rõ ràng mà không có vật cản xung quanh khu vực làm việc, vì vậy người lao động có thể dễ dàng tải và dỡ các bộ phận rất lớn từ mọi phía. Điều này không bị ảnh hưởng bởi bộ phận hỗ trợ truy cập phần nhiều mặt.

Máy CNC Gantry cũng được trang bị động cơ trục chính mạnh mẽ, thường là từ 10 mã lực đến hơn 50 mã lực. Mô-men xoắn cao, thấp từ các trục chính mạnh mẽ này cho phép loại bỏ kim loại tích cực. Việc xây dựng động và cứng có thể xử lý các lực cắt nặng đã tác dụng trong quá trình khoan và phay mạnh.

Cuối cùng, các máy CNC Gantry có khả năng gia công đa dạng, khiến chúng phù hợp với các ứng dụng như cắt plasma, cắt nước mài mòn, định tuyến và phay. Kiến trúc Gantry cung cấp sự ổn định cho gia công chính xác trên khu vực làm việc lớn. Các thay đổi trong công cụ cũng cho phép tạo hình học phần khác nhau bằng cùng một máy.

Các máy CNC Gantry thường được sử dụng trong các ứng dụng gia công nhất định sử dụng khối lượng công việc lớn của chúng và khả năng cắt kim loại mạnh mẽ. Các loại ứng dụng chính là:

Nhiều loại thiết bị và phương tiện nặng có những phần rất cồng kềnh vượt quá kích thước giường của CNC thông thường. Máy CNC Gantry có các khu vực làm việc phù hợp với các kích thước jumbo này để gia công các mảnh kim loại quá khổ.

Khung xe, cơ thể, các bộ phận thiết bị nông nghiệp, phần thân tàu và các bộ phận xây dựng kết cấu có thể có chiều dài trên 5 mét. Công suất cộng với công suất dọc theo trục X và Y của máy CNC Gantry cho phép tạo ra các bộ phận kim loại dài như vậy.

Ngành công nghiệp chế biến gỗ đòi hỏi khả năng máy móc các bộ phận gỗ khổng lồ một cách hiệu quả. Tủ bếp và màn hình, đồ nội thất khổng lồ, cửa ra vào lớn và đóng khung gỗ cần phong bì gia công phong phú.

Phần mềm làm tổ giúp tối ưu hóa việc cắt khi gia công nhiều phôi gỗ từ hàng hóa. Máy Gantry có một công trình xây dựng gồ ghề, chống mài mòn để chịu được tất cả các chip gỗ và bụi được tạo ra.

Các quá trình như cắt hồ quang plasma và cắt nước mài mòn đòi hỏi phải di chuyển trơn tru đầu cắt dọc theo trục X và Y để đạt được các mẫu cong trên vật liệu tấm.

Các máy CNC Gantry cung cấp bố cục và bản dựng mạnh mẽ để di chuyển trọng lượng đáng kể một cách trơn tru trên các trục bên này khi các tấm thép cắt lửa hoặc các lớp kim loại xếp chồng lên nước.

Máy CNC Gantry cung cấp các phạm vi hoạt động lớn dọc theo các trục tuyến tính X, Y và Z. Điều này cho phép xử lý các bộ phận kim loại hoặc gỗ cực lớn vượt quá khả năng của các CNC điển hình. Có thể tùy chỉnh để có được lớn hơn.

Khung giàn được gia cố kết hợp với dầm trên cao và hỗ trợ kết quả trong một cấu trúc mạnh mẽ, cứng nhắc. Sự ổn định động này vẫn giữ được độ chính xác khi loại bỏ các vết cắt kim loại cao.

Bố cục ngang cho phép tải các bộ phận quá khổ từ tất cả các mặt mà không bị cản trở. Công nhân có thể thuận tiện đến toàn bộ khu vực làm việc, cải thiện quy trình làm việc.

Các máy CNC Gantry có thể tích hợp công suất trục chính 50 HP hoặc cao hơn để xoay các công cụ cắt có đường kính lớn ở mức cao quan trọng để khai thác, nhàm chán và phay.

· Cấu trúc khổng lồ chiếm rất nhiều không gian sàn cửa hàng.

· Chi phí mua hàng ban đầu cao.

· Nó không linh hoạt cho các thành phần phức tạp nhỏ.

· Nó bị giới hạn trong khả năng cắt chéo.

Trung tâm gia công dọc (VMC) Đề cập đến một máy điều khiển số máy tính với trục trục chính định hướng theo chiều dọc. Điều này cho phép các hoạt động gia công như phay, khoan, khai thác, nhàm chán, v.v., được thực hiện trên một phôi được định vị theo chiều ngang.

Các phần chính của VMC bao gồm các bộ thay đổi công cụ, tạp chí công cụ, bộ điều khiển CNC, công cụ cắt, hệ thống làm mát và hướng dẫn trục X, Y và Z. Tạp chí công cụ cho phép thay đổi tự động trong các công cụ cắt.

Một trung tâm gia công dọc có một trục chính được định hướng theo chiều dọc phía trên bảng làm việc. Máy làm việc bằng kim loại hoặc nhựa được bảo đảm cho bảng này và có thể di chuyển qua lại trên trục y và ra khỏi trục X. Công cụ cắt gắn vào trục chính đi xuống. Trong hoạt động của CNC, máy điều khiển chính xác vị trí của bảng dưới trục chính, cho phép công cụ cắt xoay để nghiền và khoan các lỗ trong phôi cố định. Để thực hiện các hoạt động gia công, điều khiển trục z làm giảm máy cắt quay vào phôi ở độ sâu khác nhau. Các ốc vít dẫn chính xác trên các trục X, Y và Z định vị khu vực làm việc liên quan đến máy cắt theo hướng dẫn điều khiển số máy tính. Chuyển động 3 trục này cho phép gia công đa năng.

Định hướng dọc trong đó khớp nối trục chính nằm trên bảng làm việc giảm thiểu dấu chân máy. Kiến trúc nhỏ gọn này phù hợp với sàn sản xuất với các ràng buộc không gian.

Một cụm thay đổi công cụ tự động thường được tích hợp trong vỏ máy để hoán đổi các công cụ cắt khi cần thiết. Giảm sự tham gia của nhà điều hành thủ công.

Một cửa cố định hoặc trượt niêm phong khu vực làm việc. Điều này kiểm soát chip kim loại lỏng lẻo/ngăn chặn chất làm mát và giảm phát thải tiếng ồn xuống sàn cửa hàng để có môi trường làm việc tốt hơn.

Vòi phun làm mát thông minh trực tiếp các luồng làm mát áp suất cao đến các khu vực quan trọng như giao diện công cụ và gia công thông qua chương trình CNC, cải thiện kiểm soát nhiệt và xả chip.

Lắp ráp trục chính thẳng đứng kết nối trực tiếp với động cơ mô-men xoắn cao mà không bị mất truyền cơ học. Điều này cho phép chuyển điện tối ưu để cắt giảm nhiệm vụ.

Thiết kế cột cứng và ổ trục chính trực tiếp cho phép các trung tâm gia công thẳng đứng cho máy nghiền, khoan, lỗ khoan và thép, nhôm và titan chính xác với dung sai chặt chẽ. Các bộ phận hàng không vũ trụ và y tế thường chỉ định các yêu cầu chính xác.

Chuyển đổi nhanh chóng giữa các công việc làm cho một VMC phù hợp cho sản xuất lô nhỏ thay vì chạy dài khối lượng lớn. Pallet Pools với các phôi được xếp hàng cho phép quy trình làm việc công việc tự động.

Sau khi các quá trình chế tạo ban đầu như đúc hoặc rèn, gia công dọc thực hiện các tinh chỉnh thứ cấp như hoàn thiện bề mặt, khoan lỗ/nhàm chán và phay hồ sơ để hoàn thành các thành phần.

Từ các hợp kim hàng không vũ trụ cứng, gang và thép công cụ cứng để làm mềm các kim loại màu sắc, các nhà máy thẳng đứng thích nghi thông qua tốc độ trục chính, thay đổi dụng cụ, áp suất làm mát, v.v.

Bố cục thẳng đứng nơi trục chính nằm phía trên bàn làm việc giảm thiểu dấu chân máy cho sàn cửa hàng đông đúc. Mất ít diện tích hơn một trung tâm gia công ngang.

Có một khoang gia công kín ngăn chặn các mảnh vụn như chip kim loại và sương mù làm mát không phân tán bên ngoài. Điều này giúp duy trì chất lượng không khí của cửa hàng sạch.

Hỗ trợ cột cho trục chính cộng với phần nhô ra tối thiểu hoặc đúc hẫng góp phần vào một bản dựng cứng nhắc. Độ cứng này cho phép loại bỏ vật liệu tích cực hơn so với các nhà máy ngang kiểu đúc hẫng.

Với một trục chính thẳng đứng chỉ xuống vùng công việc, các con chip tự nhiên rơi ra mà không cần cắt lại. Các hệ thống loại bỏ chip tự động cũng có thể tích hợp dễ dàng hơn.

Dấu chân nhỏ của trung tâm gia công dọc và cách bố trí khoang phù hợp với phần tự động hóa phần pallet. Sự tham gia của công nhân được giảm thiểu với tải/dỡ bộ phận công việc tự động.

Bảng xoay lập chỉ mục mỗi công việc hướng về phía máy cắt để gia công tuần tự mà không cần thiết hoàn lại, giảm thời gian xử lý. Tất cả các yêu cầu phay, khoan và khai thác xảy ra trong một thiết lập.

· Limited X và Y Travel hạn chế kích thước phần tối đa

· Giới hạn trục chính dọc gia công của các bộ phận rất cao

· Tiêu thụ năng lượng cao hơn máy CNC ngang

· Không thể xử lý các bộ phận cực kỳ dài

Khi so sánh các máy CNC Gantry so với VMC, một số yếu tố chính để phân tích là:

Máy CNC Gantry cung cấp một phong bì công việc lớn với các chuyến đi x-y nhiều mét để xử lý các bộ phận lớn. Trung tâm gia công dọc di chuyển tối đa ở khoảng 2500 x 1200mm.

Gantry sử dụng các dầm trên cao dày bao gồm các hỗ trợ nặng nề cho độ cứng tuyệt vời. VMC đúc hẫng và cột di chuyển có thể cho phép độ lệch nhỏ dưới tải.

VMC thích ứng với các vật liệu và hoạt động khác nhau như nhàm chán và đường viền chính xác. Gantries tập trung vào khoan lực lượng cao/khai thác hoặc di chuyển các bộ phận lớn trên một khu vực rộng lớn.

Dấu chân nhỏ gọn của VMC phù hợp với tự động hóa pallet một phần. Khu vực làm việc rộng lớn của Gantry làm cho việc tích hợp tự động hóa một phần hơn.

Sau khi phân tích các điểm mạnh khác nhau giữa máy CNC Gantry và trung tâm gia công dọc, một số khuyến nghị chung có thể được đưa ra liên quan đến việc được lựa chọn tốt hơn cho các yêu cầu gia công cụ thể:

Nếu các bộ phận gia công được quá khổ với một hoặc cả hai kích thước vượt quá hành trình trục X 1500-2000mm điển hình của VMC, thì chuyển động dọc theo đường ray tuyến tính X và Y mở rộng của Gantry phù hợp hơn để định vị dưới máy cắt. Máy Gantry có khả năng di chuyển trên 5 mét có sẵn.

Gantry được gia cố cung cấp độ cứng cho các ứng dụng cắt kim loại nặng trong đó một lượng lớn thép, titan hoặc gang cần loại bỏ mô-men xoắn cao. Độ lệch được giảm thiểu mặc dù lực cắt động.

Nếu vật liệu làm việc yêu cầu giải phóng mặt bằng xung quanh tất cả các phía thay vì cố định an toàn, chẳng hạn như hàn các khung lớn hoặc kho cắt plasma, thì hướng ngang mở của Gantry tạo điều kiện cho truy cập nhiều trang web.

Khi việc sử dụng không gian sàn nhà máy cần tối ưu hóa, dấu chân nhỏ gọn của VMC mất ít diện tích hơn hệ thống giàn của Hulking cho phép đóng gói nhiều máy vào các cảnh quay vuông giới hạn.

Nếu quy trình sản xuất yêu cầu các hoạt động phay, khoan và nhàm chán khác nhau trên nhiều mặt phôi, thì việc lập chỉ mục bảng quay của các trung tâm gia công dọc cho phép hoàn thành tuần tự gia công tích hợp trong một thiết lập vật cố.

Khi các thông số gia công kêu gọi dung sai chặt chẽ, nhàm chán chính xác, đường viền phức tạp hoặc hoàn thiện bề mặt mịn, độ cứng của VMC và bộ xử lý nhanh hơn phù hợp với phép nội suy nhanh nhưng chính xác của chuyển động công cụ cắt.

Các máy CNC Gantry và trung tâm gia công dọc đều phục vụ vai trò gia công CNC quan trọng nhưng khác biệt. Cấu hình của chúng phù hợp với các ứng dụng dựa trên các yêu cầu của khu vực làm việc, độ cứng của máy, nhu cầu tự động hóa và các ràng buộc không gian sàn cửa hàng. Phân tích cẩn thận các thông số kỹ thuật và khả năng của mỗi người sẽ xác định giải pháp nào phù hợp nhất với môi trường sản xuất của bạn.