Kiểm tra thanh bi cho năm trục là công cụ chẩn đoán tiên tiến nhất áp dụng cho Máy CNC với mọi độ phức tạp và bao quát mọi chuyển động đa trục. Nó có thể xác định chính xác các loại lỗi khác nhau, bao gồm các hiện tượng hình học, sự không khớp giữa động cơ servo và độ tách rời, hoặc bất kỳ sự khác biệt nào về cấu trúc làm giảm chất lượng sản phẩm gia công.

Ngoài ra, người vận hành có thể thực hiện các bài kiểm tra nội suy vòng tròn giữa các trục theo chuỗi thời gian trước khi sản xuất thực tế. Vừa đảm bảo độ chính xác ổn định, quy trình này vừa giảm thiểu thời gian chết và cải thiện độ chính xác cho chi tiết trong các ngành công nghiệp mà độ chính xác của từng micron là rất quan trọng.

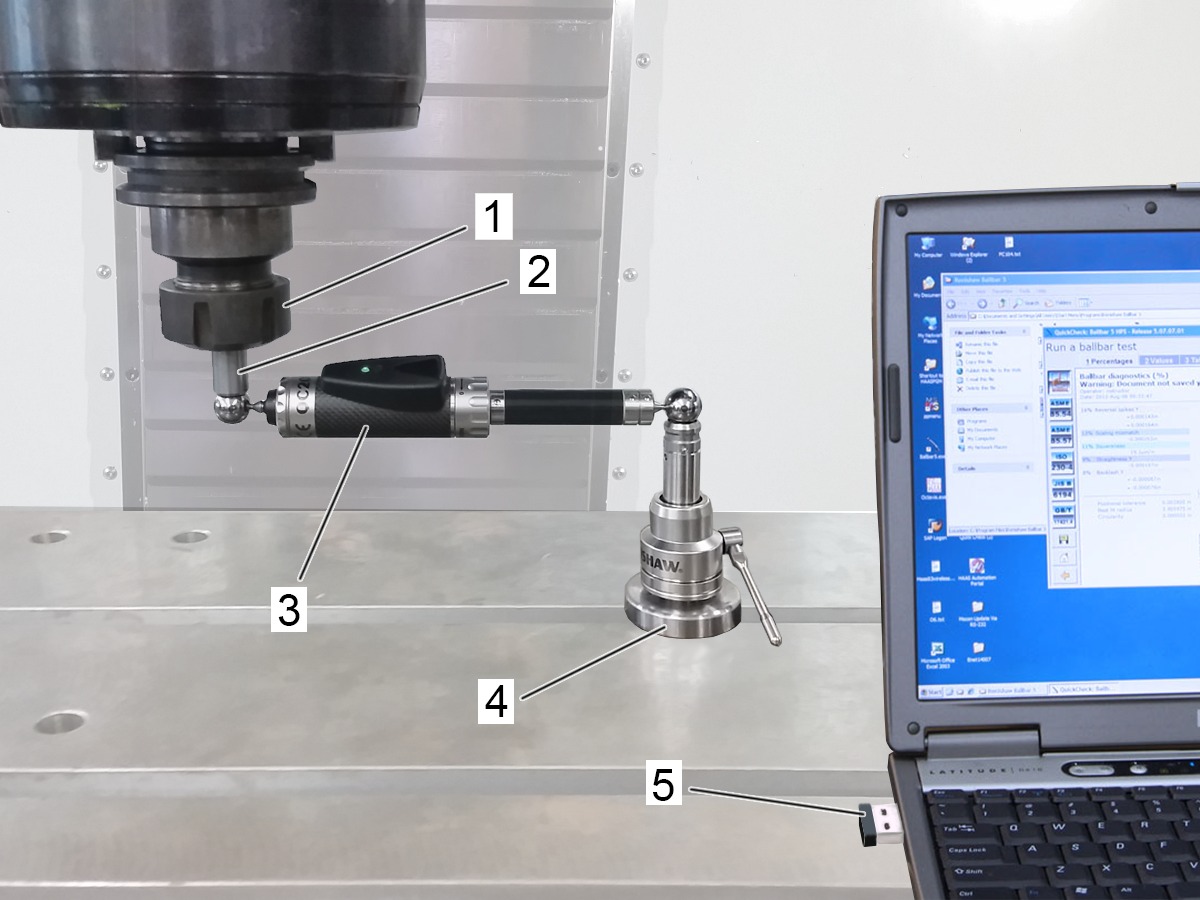

Kiểm tra thanh bi của 5 máy là một quy trình chẩn đoán hiệu quả, kiểm tra độ chính xác hình học của máy CNC thông qua các phép đo đường tròn để xác định độ chính xác thực sự của máy. Quy trình này sử dụng một thiết bị thanh bi dạng ống lồng với các viên bi chính xác ở mỗi đầu.

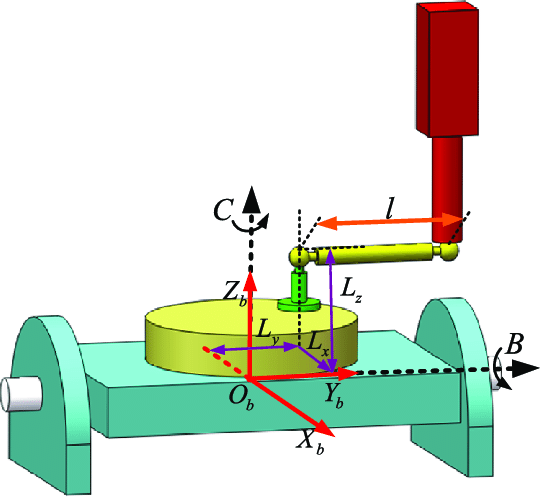

Sau đó, bằng cách gắn giữa một điểm cố định trên bàn máy và trục chính, dụng cụ sẽ di chuyển theo đường tròn đã được lập trình. Bất kỳ độ lệch nào so với đường tròn hoàn hảo đều được cảm biến ghi lại. Dữ liệu từ phép đo sẽ làm nổi bật các lỗi như khe hở, vấn đề căn chỉnh hoặc servo không khớp.

Bài kiểm tra hiện được mở rộng với các trục quay và trục nghiêng theo cấu hình 5 trục, khiến bài kiểm tra phức tạp hơn một chút nhưng hiệu quả hơn nhiều trong việc hiểu tình trạng chung của máy.

Gia công CNC hiện đại đòi hỏi độ chính xác cao, đặc biệt trong trường hợp dung sai chặt chẽ và tạo hình các chi tiết phức tạp. Ngay cả khi được bảo dưỡng tốt nhất theo thời gian, xu hướng hao mòn rõ rệt hơn vẫn có thể xuất hiện ở các thanh dẫn hướng, ổ trục hoặc khớp quay.

Thử nghiệm thanh bi sẽ phát hiện những điều này sớm hơn nhiều, và một hình ảnh lập bản đồ sẽ được tạo ra về cách tất cả các trục hoạt động trong quá trình chuyển động. Ví dụ, nếu trục quay hơi lệch một góc, điều đó sẽ được hiển thị dưới dạng độ lệch so với mô hình vòng tròn.

Khi thực hiện bài kiểm tra này thường xuyên, người ta có thể nhận biết được những điều sau:

• Phát hiện sớm các lỗi hình học và động lực học.

• Giảm thời gian chết.

• Duy trì độ chính xác gia công.

• Tránh việc phải làm lại hoặc từ chối tốn kém.

Thanh trượt là trung tâm của hệ thống kiểm tra thanh bi. Nó hoạt động như một cảm biến tuyến tính chính xác, được thiết kế để đo những thay đổi cực nhỏ về khoảng cách khi máy CNC thực hiện chuyển động tròn. Bất kỳ độ lệch nào được thanh trượt phát hiện đều cho thấy lỗi định vị hoặc sai lệch cơ học trong hệ thống. Nó có độ nhạy rất cao, cho phép ghi lại các biến thiên chuyển động theo thời gian thực và cho phép chẩn đoán chính xác hiệu suất máy.

Các cốc từ giữ chặt các viên bi chính xác tại vị trí cố định trong quá trình thử nghiệm. Chúng có nhiệm vụ duy trì kết nối an toàn và ổn định giữa các đầu thanh và các bộ phận của máy. Chỉ cần một chút hao mòn, bụi bẩn hoặc sai lệch nhỏ nhất trong các cốc này cũng có thể khiến kết quả đo không chính xác hoặc dữ liệu bị bóp méo. Do đó, cốc từ phải được kiểm tra và vệ sinh thường xuyên để có kết quả thử nghiệm đáng tin cậy.

Trong quá trình thử nghiệm, quả cầu hiệu chuẩn được sử dụng như một điểm tham chiếu cứng và ổn định. Nó trở thành cơ sở hình học mà thanh đo kính thiên văn dựa vào để đo, đảm bảo tất cả dữ liệu được ghi lại đều tham chiếu đến chuẩn đã biết, có độ chính xác cao. Nếu quả cầu được hiệu chuẩn đúng cách, nó sẽ đảm bảo độ chính xác thử nghiệm tổng thể đồng thời giảm thiểu độ không chắc chắn của phép đo.

Đồ gá lắp đóng vai trò quan trọng trong việc căn chỉnh hệ thống thanh bi với trục chính và bàn máy CNC. Việc căn chỉnh chính xác sẽ cho phép các phép đo từ thanh bi thể hiện chuyển động thực sự của máy, thay vì các lỗi đo lường phát sinh trong quá trình thiết lập. Đồ gá chất lượng tốt sẽ loại bỏ rung động, ngăn ngừa trượt và thúc đẩy tính nhất quán tổng thể trong quá trình thử nghiệm.

Đây là công cụ front-end xử lý tín hiệu thô từ thanh trượt thu gọn thành biểu đồ lỗi trực quan hoặc biểu đồ chẩn đoán. Các biểu đồ này hữu ích trong việc xác định các vấn đề cơ học như độ rơ, độ trễ servo hoặc lỗi vuông góc.

Ngày nay, các gói phần mềm sẽ tạo ra các báo cáo phân tích chuyên sâu, giúp các kỹ thuật viên khắc phục sự cố và hiệu chuẩn máy.

Các thử nghiệm sử dụng thanh bi dựa trên một nguyên lý đơn giản nhưng mạnh mẽ. Máy mô tả một đường tròn, trong khi một cảm biến trong quá trình di chuyển sẽ đo độ lệch của bán kính.

Quá trình này thường diễn ra như sau:

• Thanh bi được lắp giữa điểm tham chiếu trên bàn và giá đỡ trên trục quay.

• CNC được lập trình để di chuyển theo đường tròn.

• Bất kỳ độ lệch nào so với bán kính lý tưởng đều được đo khi trục chính di chuyển theo đường tròn.

• Thông tin này được chuyển đổi thành biểu đồ cực hoặc biểu đồ độ lệch bằng phần mềm.

Đường tròn được mô tả càng ít và càng đồng đều thì độ chính xác của máy CNC càng cao. Trong hệ thống 5 trục, thử nghiệm tương tự cũng được áp dụng cho các trục quay để kiểm tra độ nghiêng và độ chính xác khi quay.

Bài kiểm tra thanh bi 5 trục đo lường các thông số khác nhau được coi là chỉ số quan trọng về hiệu suất chính xác hình học của máy CNC. Mỗi thông số sẽ cung cấp thông tin chi tiết cụ thể về tình trạng chung của máy và chất lượng chuyển động.

Độ lệch tròn là thước đo sự khác biệt giữa quỹ đạo chuyển động tròn được xác định trước. Máy thực sự đã đi qua quỹ đạo này. Nếu độ lệch tròn lớn, nguyên nhân có thể là do sai số hình học hoặc trục không thẳng hàng.

Rõ ràng là cần phải hạn chế độ lệch tròn để đảm bảo độ chính xác kích thước chi tiết khi gia công nhiều trục. Độ lệch tròn hạn chế sẽ mang lại sự tin cậy cho quá trình gia công.

Độ rơ được định nghĩa là độ rơ hoặc mất chuyển động của máy trong quá trình thay đổi đường truyền. Nguyên nhân có thể là do linh kiện bị mòn, khớp nối lỏng lẻo, điều chỉnh servo không đúng cách, hoặc kết hợp các yếu tố này. Độ rơ quá mức có thể dẫn đến sai số kích thước, vấn đề về độ hoàn thiện bề mặt hoặc chất lượng chi tiết không đồng đều.

Độ vuông góc xác định độ chính xác của hai trục vuông góc giao nhau với máy móc. Bất kỳ sự sai lệch nào trên các trục này đều sẽ gây ra lỗi khi gia công các chi tiết góc cạnh hoặc các bộ phận góc cạnh.

Việc thực hành liên tục kiểm tra thanh bi giúp phát hiện độ vuông góc. Vẫn có thể can thiệp và khắc phục vấn đề, giúp cải thiện độ chính xác hình học.

Sự tăng đột biến về sai số vị trí khi máy CNC thay đổi hướng nhanh được gọi là đột biến đảo chiều. Chúng biểu thị độ trễ servo, độ rơ cơ học hoặc chuyển động không đồng bộ của trục.

Theo dõi các xung đột đảo ngược để hỗ trợ kỹ thuật viên điều chỉnh hệ thống điều khiển và cải thiện khả năng phản hồi của máy.

Sự không khớp tỷ lệ xảy ra khi một trục di chuyển nhanh hơn hoặc chậm hơn một chút so với trục kia trong quá trình chuyển động phối hợp. Sự không khớp như vậy có thể khiến phép nội suy cung tròn trở nên không chính xác, và do đó, dẫn đến sai lệch về kích thước.

Phát hiện và hiệu chỉnh sự không khớp tỷ lệ đảm bảo chuyển động trên các trục khác nhau diễn ra trơn tru và đồng bộ.

Quy trình thực hiện xét nghiệm. Do độ chính xác cao để đánh giá hiệu quả chính xác, quy trình đầy đủ được mô tả như sau:

Máy CNC phải được làm nóng trước để đạt đến nhiệt độ lắp đặt. Điều này giúp giảm thiểu các sai số liên quan do giãn nở nhiệt, đồng thời cho phép xác định cơ học trong điều kiện vận hành ổn định.

Thiết bị thanh bi được đặt giữa trục chính máy và bàn máy, thông qua giá đỡ từ tính hoặc cơ học. Việc lắp đặt phải được thực hiện sao cho cả hai đầu của thanh bi được cố định chắc chắn. Sau khi lắp đặt, không xảy ra rung động hoặc chuyển động trong quá trình thử nghiệm.

Thiết lập chính xác tham chiếu không gian của máy cho thiết lập liên quan đến đường tâm hoặc vị trí tham chiếu. Nếu căn chỉnh không được đảm bảo, mọi chuyển động và phép đo của máy sẽ phản ánh lỗi thiết lập và không thực sự thể hiện hình dạng máy.

Tải chương trình chuyển động tròn vào bộ điều khiển CNC. Chương trình này điều khiển máy thực hiện các chuyển động theo đường tròn chính xác. Nó thường theo các bán kính và tổ hợp trục khác nhau (XY, YZ, XZ, v.v.).

Áp dụng các bài kiểm tra thanh bi theo các chuyển động đã lập trình. Đối với máy 5 trục, các bài kiểm tra cũng nên bao gồm các chuyển động quay. Máy cũng nghiêng các trục để kiểm tra sự đồng bộ và điều khiển trục song song.

Hệ thống thanh bi sẽ ghi lại những sai lệch này so với đường tròn thực tế của bài kiểm tra. Lưu trữ ảnh chụp màn hình và kết quả kiểm tra được tạo ra cho tất cả các chu kỳ để xem lại sau.

Dữ liệu được ghi lại cần được đánh giá bằng phần mềm phân tích thanh bi. So sánh kết quả với tiêu chuẩn dung sai hoặc thông số kỹ thuật của nhà sản xuất để xác định bất kỳ lỗi hình học, độ rơ, chuyển động vuông góc hoặc sự không khớp servo nào.

Hiện tượng này xảy ra khi có khe hở nhỏ hoặc độ rơ giữa các bộ phận truyền động. Khi máy đổi hướng, chuyển động dường như bị chậm lại. Điều này làm giảm độ chính xác và chuyển động không đều. Độ rơ thường ảnh hưởng đến độ chính xác của đường viền. Độ rơ có thể đủ lớn để tạo ra các khuyết tật nhìn thấy được trên bề mặt gia công, chủ yếu trong quá trình hoàn thiện tinh xảo.

Sự không đồng bộ servo xảy ra khi các trục khác nhau của máy tăng tốc hoặc giảm tốc ở các tốc độ khác nhau. Điều này dẫn đến đường tròn bị biến dạng, và chuyển động của dụng cụ trở nên rất không đồng đều. Nó sẽ tạo thêm ứng suất cơ học lên động cơ servo và hệ thống truyền động, ảnh hưởng đến hiệu suất gia công và độ tin cậy của máy.

Lỗi này phát sinh khi các trục tuyến tính của máy không vuông góc với nhau hoàn toàn. Điều này dẫn đến sai lệch góc, khiến hình dạng tổng thể của chi tiết gia công bị biến dạng. Độ lệch vuông góc nhỏ sẽ gây ra sự khác biệt về kích thước khi gia công nhiều trục, đặc biệt là đối với các chi tiết chính xác.

Rối loạn độ lệch xảy ra khi trục quay hoặc trục nghiêng không thể xoay đến một góc thích hợp. Nó dẫn đến lỗi định hướng dụng cụ, đặc biệt là trong gia công 5 trục phức tạp. Độ lệch như vậy có thể ảnh hưởng đáng kể đến độ chính xác của các bề mặt cong và lỗ góc kép.

Độ rơ cơ học xảy ra do vít hở, ổ trục bị mòn hoặc bất kỳ sự lỏng lẻo cơ học nào khác. Điều này gây ra rung động và mất ổn định, ảnh hưởng trực tiếp đến độ chính xác gia công. Vận hành liên tục với sự cố cơ học cũng có thể dẫn đến hỏng hóc sớm các bộ phận hoặc chất lượng không đồng đều. Lỗi này có thể được khắc phục bằng cách căn chỉnh lại và điều chỉnh thông số thay thế linh kiện.

Để có kết quả tốt nhất trong các bài kiểm tra thanh bi đáng tin cậy, bạn nên cân nhắc các biện pháp tốt nhất sau đây:

●Luôn làm nóng máy trước khi thử nghiệm.

●Môi trường phải luôn ổn định, đặc biệt là về nhiệt độ và độ ẩm.

●Vệ sinh trục chính, bàn máy và đồ gá trước khi lắp.

●Việc đọc số không bị cản trở bởi rung động hoặc gió lùa.

●Độ dài thanh bi phù hợp với khu vực làm việc của máy.

●Hiệu chỉnh lại thanh bi thường xuyên.

Việc kiểm tra không thành công sẽ đảm bảo hình dạng của máy được căn chỉnh tốt. Sản phẩm sẽ được sản xuất với dung sai chặt chẽ hơn. Cuối cùng, việc căn chỉnh tốt hơn sẽ cải thiện khả năng lặp lại của từng chi tiết được sản xuất theo kích thước tiêu chuẩn.

Kiểm tra thanh bi sẽ cho phép bạn theo dõi, phát hiện và ngăn ngừa các hư hỏng sớm do nguyên nhân mài mòn cứng. Việc mất cân bằng liên quan đến sự cố hỏng hóc đột ngột sẽ giúp giảm thời gian bảo trì ngoài kế hoạch, giảm thiểu gián đoạn sản xuất và cải thiện hiệu quả chung của nhà máy.

Một máy móc được tinh chỉnh tốt sẽ hoạt động hiệu quả mà không gặp bất kỳ trục trặc nào. Thời gian chu kỳ sẽ được rút ngắn và hiệu quả gia công tổng thể sẽ được cải thiện. Năng suất cao hơn đồng nghĩa với việc người vận hành sẽ đạt được sản lượng lớn hơn mà không ảnh hưởng đến chất lượng của các chi tiết được sản xuất.

Kết quả là, thử nghiệm loại bỏ các lỗi kích thước, giảm thiểu các chi tiết bị loại bỏ và giảm thiểu lãng phí vật liệu. Độ chính xác nhất quán trong gia công giúp tiết kiệm cả nguyên liệu thô và thời gian sản xuất, trực tiếp giảm chi phí sản xuất.

Small tìm ra những sửa chữa hoàn hảo trước khi quá tải cơ học gây hư hỏng và kéo dài tuổi thọ chung của máy CNC. Hiệu chuẩn đúng cách giúp các linh kiện luôn ở mức tải tối ưu và do đó bảo vệ chúng khỏi bị hao mòn theo thời gian.

Việc kiểm tra thường xuyên đảm bảo máy đáp ứng các tiêu chuẩn độ chính xác quốc tế như ISO 230-4 và ANSI B5.54, qua đó đảm bảo tiêu chuẩn sản xuất chất lượng cao. Việc tuân thủ cũng đồng nghĩa với việc chiếm được lòng tin của khách hàng và đáp ứng các yêu cầu chứng nhận về gia công chính xác.

Kiểm tra thanh bi 5 trục không chỉ nhằm mục đích chẩn đoán tại chỗ. Nó cũng là một phần của bảo trì dự đoán dài hạn. Việc ghi lại kết quả kiểm tra theo thời gian có thể cho thấy những thay đổi dần dần về hiệu suất máy. Nó có thể cho thấy sự gia tăng độ lệch nếu vít me bi hoặc thanh dẫn hướng bị mòn.

Việc sử dụng dữ liệu thanh bi để dự đoán cho phép nhóm bảo trì thực hiện những việc sau:

• Lên lịch thay thế linh kiện kịp thời.

• Tránh sự cố đột ngột.

• Tùy chỉnh khoảng thời gian bảo dưỡng để phù hợp với hành vi thực tế của máy.

Lỗi chuyển động cân bằng, mất cân bằng servo và các nguồn sai số hình học là một phần của quá trình kiểm tra thanh bi. Kết quả chuyển động tròn cho thấy rằng một phân tích có thể phát hiện ra các lỗi tiềm ẩn trong quá trình hiệu chuẩn thông thường.

Kiểm tra thanh bi có hiệu quả cao, nhờ đó có thể phát hiện ra lỗi. Tuy nhiên, nguồn gốc thực sự của các sai lệch đáng kể không bao giờ có thể được xác định bằng mắt thường. Nếu báo cáo kiểm tra cho thấy các vấn đề nghiêm trọng, cần phải kiểm tra chi tiết hơn. Phân tích hiệu chỉnh vẫn có giá trị trong việc xác định và khắc phục các vấn đề gốc rễ, chẳng hạn như ổ trục bị mòn hoặc trục bị lệch.

Một quan niệm sai lầm khác là việc kiểm tra thanh bi mất nhiều thời gian để sản xuất. Thực tế là hầu hết các bài kiểm tra tiêu chuẩn chỉ có thể được thực hiện trong vòng 20 đến 30 phút, bao gồm cả việc thiết lập và phân tích. Do đó, các công cụ chẩn đoán nhanh chóng và hiệu quả giúp giảm thiểu thời gian ngừng hoạt động của máy móc.

Nguyên lý kiểm tra thanh bi có thể được áp dụng chung cho tất cả các loại máy CNC. Chúng là hệ thống 3 trục, 4 trục hoặc 5 trục. Tất cả đều tuân thủ cùng một phương pháp chuyển động tròn để đánh giá độ chính xác định vị. Phân tích hiệu suất của máy trong mọi loại cấu hình.

Kiểm tra thanh bi 5 trục là một quy trình chẩn đoán đơn giản nhưng hiệu quả trong máy CNC, giúp duy trì độ chính xác và hiệu suất. Việc đo độ lệch tròn và xác định các lỗi cơ học ngay từ giai đoạn đầu đảm bảo tính nhất quán về chất lượng, giảm thời gian ngừng hoạt động và kéo dài tuổi thọ máy. Kiểm tra thường xuyên là một khoản đầu tư khôn ngoan để đảm bảo độ chính xác và độ tin cậy cho hệ thống CNC 5 trục của mọi nhà sản xuất.